Hybrid Composite Bridge Beams

HC Bridge Company & Poletech

Applications

- Bridges spans up to 120 feet and more either as individual beams or as a component of a prefabricated bridge elements and systems (PBES), ideal for Accelerated Bridge Construction (ABC)

- Marine Structures (Caps, crane beams and decks for Piers, Wharves, etc)

- Roofs and decks, especially in corrosive environments or “green” roofs

- Bridges perfect for Roadway and Railway sturcutres

Why HCBs Create Better Structures

- Sustainable: No rusting, cracking, spalling or alkali-silica reactions (ASR) provides a 100+ year service life and never needs painting

- Lightweight: Shipping and erecting weight is approximately 10 percent of a concrete beam and 33 percent of a steel beam. This allows greater flexibility for installing the beams.

- Congestion Relief: Lighter, modular bridge system allows for “Accelerated Bridge Construction” and reduced traffic congestion during construction.

- Safer: Internal redundancy and serviceability design result in capacities that greatly exceed code requirements.

- Reduced mass and resilient, energy absorbing materials offer excellent resistance and elastic response to seismic forces. Reduced Carbon Footprint: Hybrid-composite beams use 80 percent less cement – one of the largest contributors to the carbon footprint. The beams also require 75 to 80 percent fewer trucks for shipping and smaller cranes for erection for reduced carbon emissions.

What is HCB ?

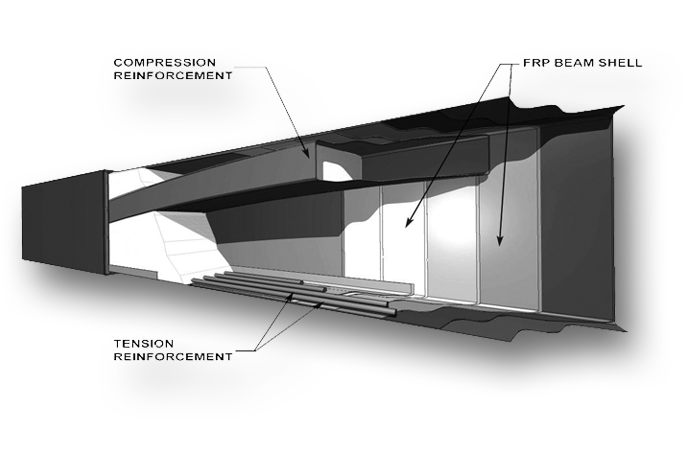

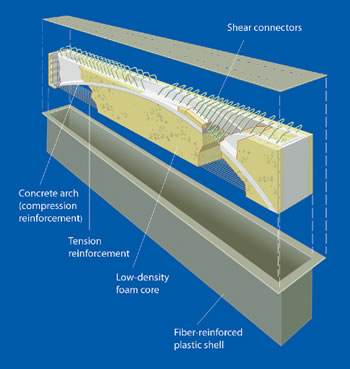

Simply put, HCB (Hybrid-Composite Beam) is a revolutionary, sustainable technology that combines the strength and stiffness of conventional concrete and steel with the lightweight and corrosion resistant advantages of fibre reinforced polymers (FRP). Though the HCB may appear unconventional, but the design, fabrication and construction processes are simple and familiar to design and construction professionals. As a structural system, the HCB is not a plastic structural member.

Virtually all of the strength and stiffness of the beam is derived from concrete and galvanised pre-stressing strand. Safety is inherently built into HCBs and the strength capacity consistently exceeds code requirements. Couple this inherent safety with corrosion resistant properties of the HCB and you have a structure that lasts longer with less maintenance. By optimising the inherent qualities of the three components (FRP shell, compression reinforcement and tension reinforcement), the HCB allows construction professionals to build better structures that are cost competitive, stronger and require no additional training for their crews.

Greta Bridge Composite Bridge Beam during manufacturing.

FOR MORE INFROMATION

CALL US - 02 6574 6012