PoletechComposites Power Poles

Cost Efficient Installation

Non - Conductive System

Strong and Resistant

Advantagesof the composite power pole system

Lightweight

The composite power pole is on average 40% lighter than the equivalent rated timber pole.

Corrosion & Termite Resistant

The composite power pole is construction from Epoxy Vinyl Ester Resin giving it resistance to Caustic Alkalis, Hypochlorite Bleaching Chemicals and high temperatures and termites.

Cost Efficient Installation

The composite power pole is installed in similar fashion to the timber pole however being lighter it is more cost effective to install in those applications with access restrictions.

Non - Conductive System

The composite power pole is inert and the structure is non conductive. Our poles have successfully undergone testing at Ergon Energy results are available upon request.

The composite power poles are manufactured in a cylindrical taper shape similar to the timber pole. This means that all current hardware such as cross arms & bolt on foot pegs and there fitment to the pole will be done the same way or using a similar method.

Transport & Storage

Composite power poles can be transported, stored & handled in the same way timber poles are, with consideration taken to protect the surface of the pole, this simply means nylon straps in place of chains & dogs. Because the power poles are lighter in weight. Transport costs become more efficient.

Life Expectancy

Composite power poles based on US & European manufactures data & studies have a life expectancy of 70-80 years combined with the other advantages of fire corrosion, termite, rot resistance & lower transportation cost the composite poles installed cost becomes extremely competitive .

Fire Resistant

The power poles are constructed from fire retardant laminates. We have conducted tests in accordance to AS 1530.8.2 Simulated bushfire attack – Large flaming source. Along with Californian brush fire tests.

Poletech's FIRE Resistant Composite Power Poleswithstood the devastating Black Summer fires of 2020, in Australia.

Fire Testing -Composite Power Power Fire Test at CSIRO

Testing and Certification

Finite Element Analisis (FEA)

Poletech engage the independent services of EMP and Green Storm Solutions to conduct FEA on the design of our pole. The FEA working load consist of transverse tip load equivalent to half the ultimate load and is used to define the serviceability limit state.In this condition the pole deflection has been limited to less than 5% of the cantilevered length. This location corresponds with the recommendations in 'AS/NZS 4676:2000 Structural design requirements and AS/NZS 7000:2016 Overhead Design for Power Poles'.

The Poletech power pole, are manufactured with a UV Stabilized and protective outer barrier of the pole. This ensures the ultimate extended life of the poles.

Environmentally Friendly Materials

Poletech power poles are manufactured from environmentally friendly materials. There are no toxic preservatives to leach out into the soil or ground water around the pole.

Downsizing of installation Plant & Overheads

Being lighter, the composite poles can be installed using smaller plant & equipment. This in turn creates a smaller installation footprint that can save on public impact & disruption such as road or lane closures during installation. The smaller plant also results in an improved safety interface with the public.

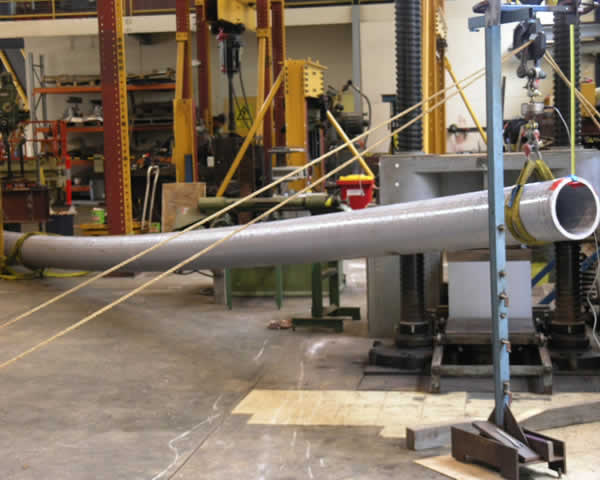

Poletech -Load Testing

Poles are tested in accordance with AS/NZS 4676.2000 and AS/NZS 7000:2016 Overhead Design . Initial load testing was conducted at the University of Queensland's Department of Civil Engineering Testing facility in St Lucia. Ongoing production tests are independently verified in house by Green Strom Solutions.

- UQ testing official prepares a 12.5m one piece pole for load test.

- The 12.5m, one piece pole during a load test.

- The 12.5m, one piece pole during a destructive test breaking point was 32Kn

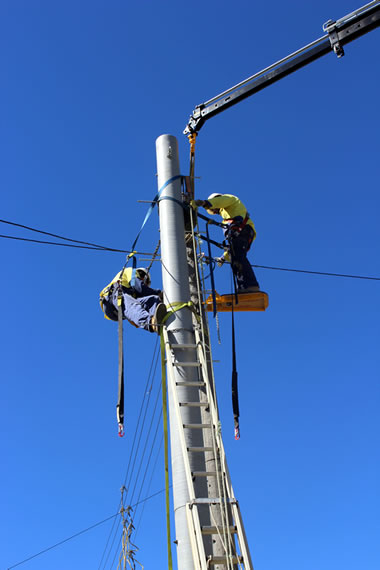

Poletech -Electrical Testing

Below are images of Ergon Energy's Testing Facility and Testing procedures. Workers at the Testing Facility setting up a Utility Pole prior to a lightning impulse test.